Coil, Motor and Transformer

Coils and power transformers are used in almost all electronic products. Its principle is simple, but according to different uses, the winding process of the transformer will have different requirements.

Motors are commonly found in electric machine tools.

In recent years, power electronic products have developed toward lightness, thinness, and shortness, and related peripheral products have also progressed toward interfaces that are light, thin, short, and easy for people to operate. Therefore, the design and innovation of electronic transformers, which are key components, not only need to improve efficiency and save energy but lead to flat and lightweight structure.

The products in this market that our company can provide include:

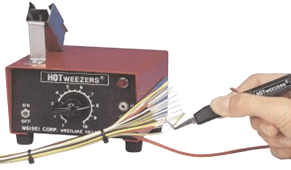

Fully Insulated Wire, Triple Insulate Wire, Conformal Coating, Varnish, Hotweezer, Lead-Free solder

Transformer & Coil

Transformers are widely used in daily life. Their main function is to change high voltage to low voltage, or to change alternating current to direct current/direct current to alternating current. It is often used in ordinary daily life in mobile phones, notebook charger, etc. Insulated wires can be used for secondary winding in transformers. Vanish is used to improve product insulation, fixation, moisture-proof and rust-proof; conformal coating is for better protection. HoTweezer and Lead-free solder are used for wire rack welding.

Motor

The motor is the core component of the power tool unit, and its composition is mainly composed of a stator and a rotor. The stator is stationary in the space, while the rotor can rotate around the shaft and is supported by bearings. There will be a certain air gap between the stator and the rotor to ensure that the rotor can rotate freely. After being energized, electric energy is converted into kinetic energy through electromagnetic induction. The wire is used for winding, and varnish and conformal coating are used for insulation protection.