Semiconductor Testing

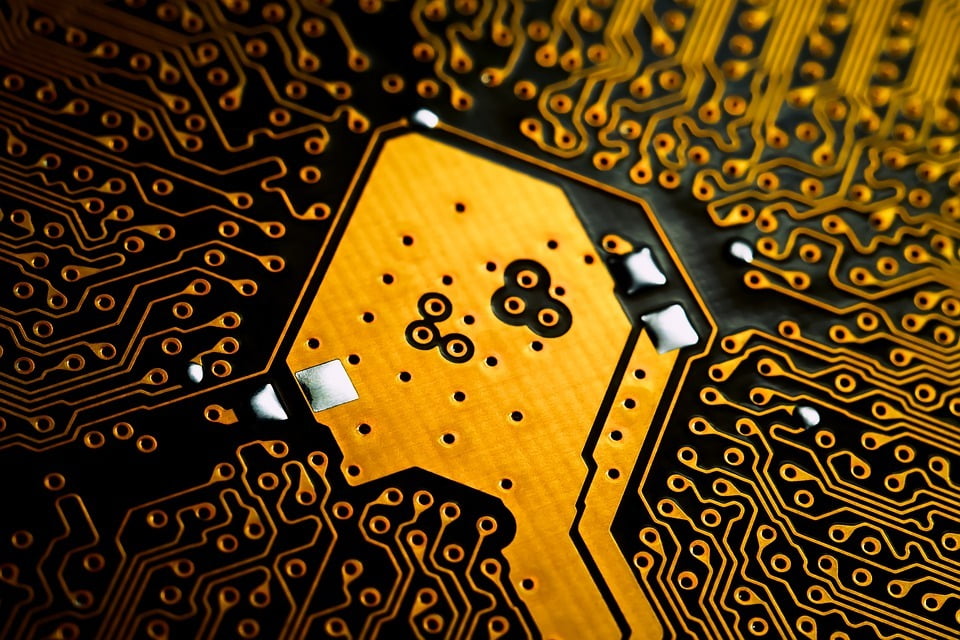

WE confirm the structure and function of a completed semiconductor original or integrated circuit (IC) to ensure the integrity and normality of the IC or component when it reaches the system. We call it testing.

Why do we have to test? The IC manufacturing process can never reach 100% yield. Therefore, before putting the IC on the system, it must be tested to determine the normality and integrity of the IC function to reduce the cost.

The products in this market that our company can provide include:

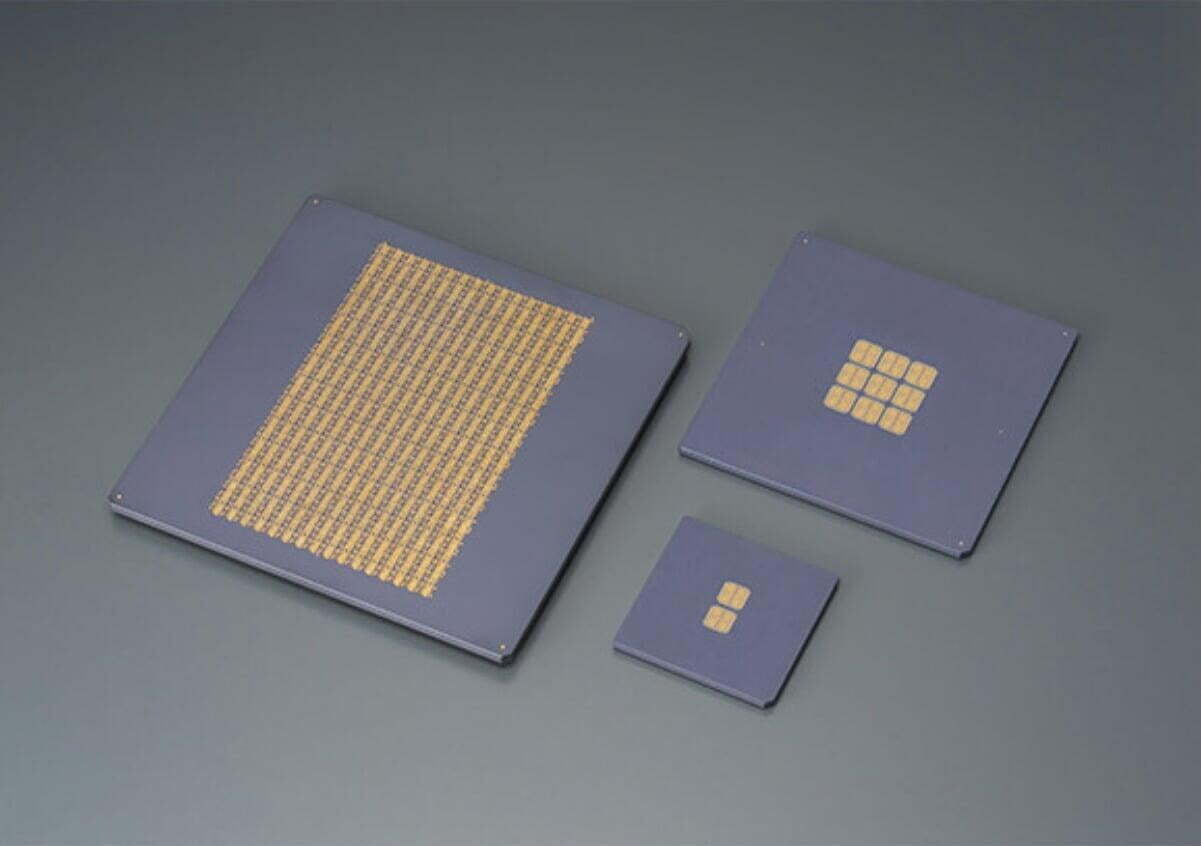

PCB, Probe, Insulated Tube, MLC, Ceramic, Lead-Free Solder

Phase 1. Wafer Test

A probe test is carried out for each die on the wafer, so that the IC can filter out the chips with poor electrical function before packaging, so as to reduce the defective rate of the IC product and avoid increasing the manufacturing cost.

Phase 2. Final Test

For the test after the package is formed, it is confirmed whether the function, speed, tolerance, power consumption, heat dissipation and other properties of the IC finished product are normal to ensure the quality of the IC before shipment.