Varnish

Varnish

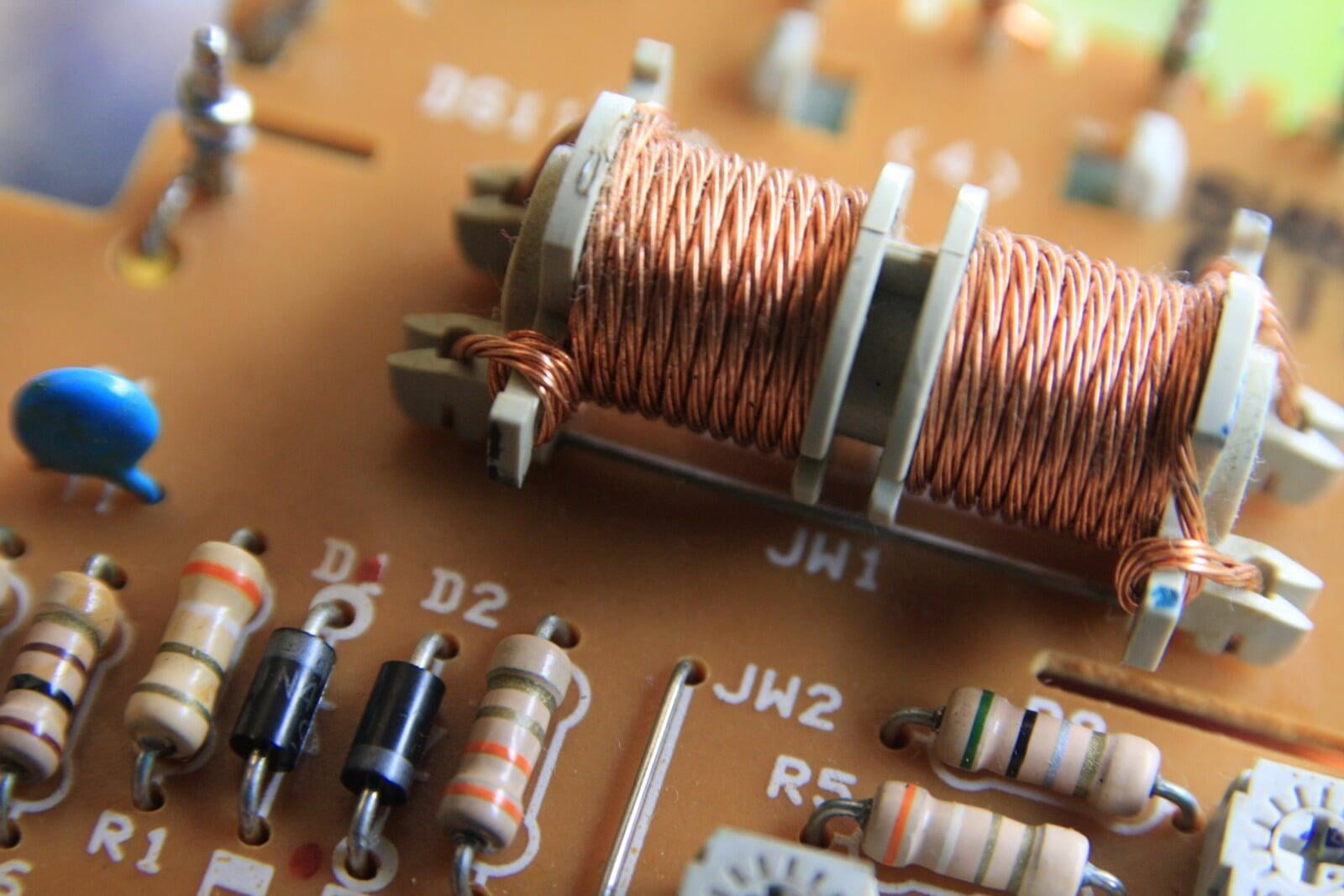

Varnish is the common name for insulating paint. It is an important insulating material based on high-molecular polymer that can be cured into an insulating film or insulation under certain conditions. Vanish is used for impregnation or coating of transformers, coils, and enameled wires. It is widely used in electrical products and electronic parts, various types of coils, transformers, PC circuit boards, resistors, generators, etc.

Our company acts as the agent of the world's leading brand: Resonac (Hitachi Chemical) Vanish.

Resonac (Hitachi Chemical) mainly produces non-solvent varnish water. Compared with the common commercially available solvent-based Vanish, the differences are as follows:

According to UL heat-resistant temperature, our current sales products can be divided into three categories:

1. 155°C (Class F): WP-2952F-2GY

Being mainly used in high-frequency transformers for low-temperature baking and fast hardening with excellent plasticity. It can be matched with more than 70 sets of mainstream insulation systems.

2. 180℃(Class H):WP-2854

Being mainly used in the stator and rotor of electric tools and home appliances. It has strong high temperature adhesion and rapid hardening.

3. 200℃(Class N):WP-2008

Being mainly used in products with low VOC requirements, such as automobile stators and rotors. Solvent-free epoxy resin varnish, with no added styrene.

4. 220℃(PAI resin):HCI-100

High heat-resistant polyamide-imide resin solution (Polyamide-imide, PAI). Being mainly used in non-stick pan coatings and metal processing parts, such as pistons, cams and other lubricating coatings