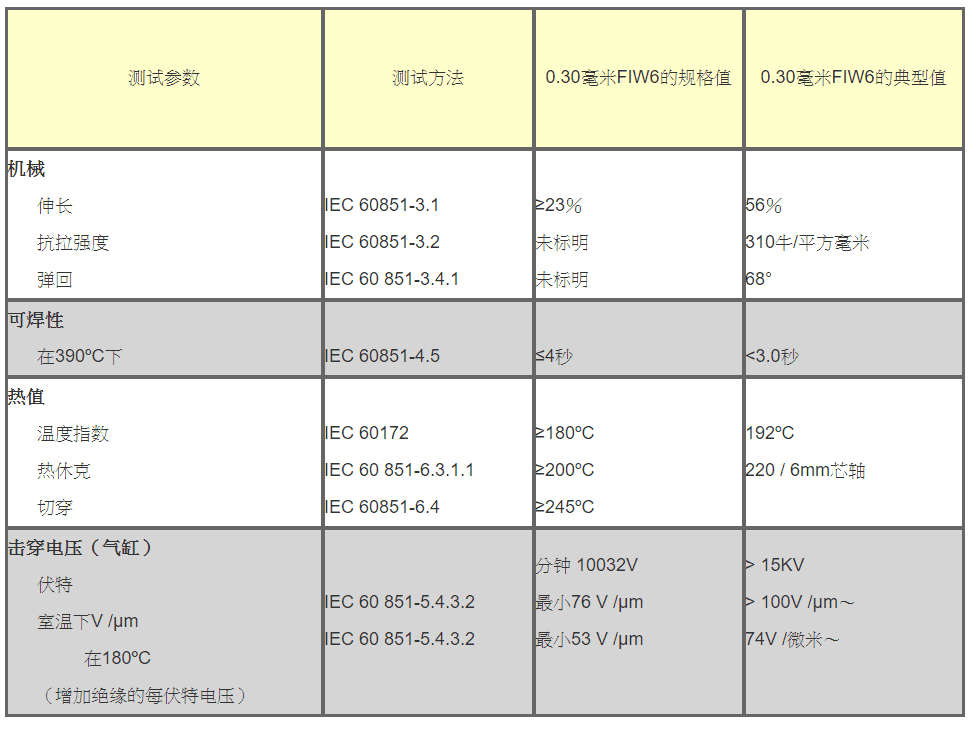

Fully Insulated Wire (FIW) is a wire product that can replace traditional TIW (Triple Insulated Wire) for the production of switching transformers. Due to the wide selection of finished FIW outer diameters, it allows customers to produce smaller transformers at a lower cost. At the same time, FIW has better winding performance and soldering performance than TIW.

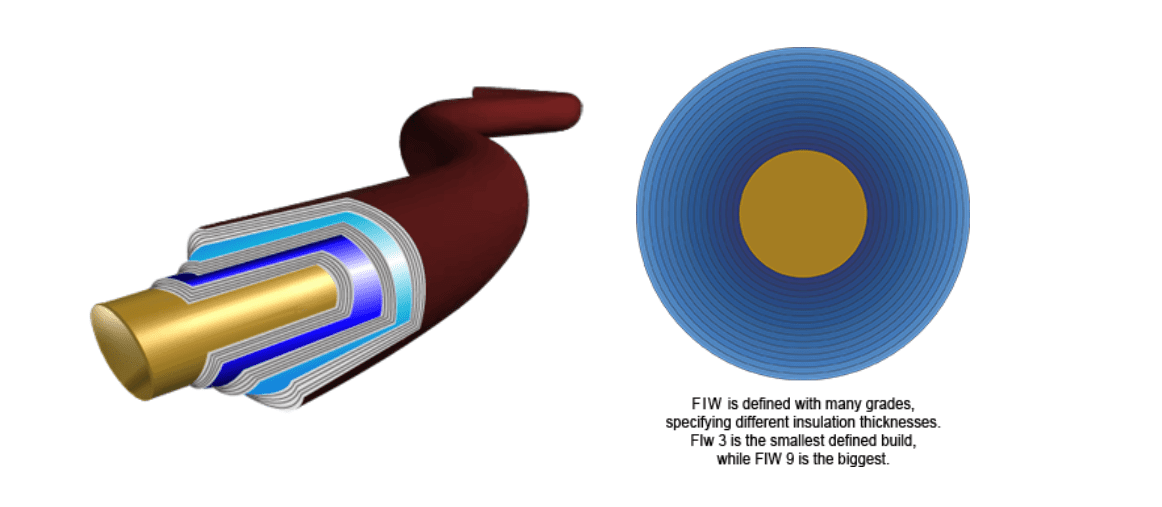

In FIW adopts a multiple coating process and has undergone more than 30 coating treatments to ensure reliable and defect-free insulation.

FIW defines a number of different levels to specify different insulation layer thicknesses, reaching the following grades of FIW3, FIW4, FIW5, up to FIW9; for example, FIW3 0.050mm wire has a maximum total diameter of 0.072mm, which is the smallest. The breakdown voltage is 3,000 volts. FIW8 0.050mm welding wire has a maximum total diameter of 0.127mm and a minimum breakdown voltage of 8,000 volts.

- Different insulation layer thicknesses can be selected, allowing product optimization. Such as reducing the size of the transformer and reducing the cost.

Excellent solderability.

Excellent windability.

Being based on IEC 60172, FIW can reach a high temperature class of 180 °C.

The heat resistance of 0.10-0.71 mm wire diameter tested according to UL 2353 appendix U has obtained the certification of Class B (130 °C) and Class F (155 °C), and the wire diameter of 0.10-0.50 mm has also obtained 155 °C temperature class reinforced insulation certification.

It has UL insulation system certification for enameled wire, and its safety has been verified through years of use.

FIW is usually a 180-class enameled round copper wire with a single layer coating based on polyurethane resin. This is why the specifications and technical data in general match. P.Leo catalog number FIW (MW85-C) and Ul file number E158033 in accordance with IEC 60317.

However, due to the special requirements for "weldable wires with fully insulated zero defect," some specifications are beyond the previous scope. The special technical values of FIW are specified in IEC 60317-0-7 and IEC 60317-56 and compared with the typical values of P. Leo FIW on our IEC 60317-56 page. P.Leo FIW meets and exceeds the FIW requirements of IEC 60317-56.

In addition, there are also some specific requirements for the FIW test conditions in the standard IEC 60950 (Annex U) for safety and information technology equipment. The typical results of P.Leo FIW shown on page U of IEC 60950 Annex show that P.Leo FIW also meets the requirements of IEC 60950 (Appendix U).

IEC62368-1 is an integration of IEC 60950-1 and IEC 60065 standards and was released in 2014.

As new equipment and applications develop at an unprecedented speed and technology continues to merge, IEC62368-1 increases the requirements for fully insulated winding wires (FIW).