In recent years, semiconductor test platforms have rapidly advanced toward high-frequency operation, multi-module integration, and thermal cycling validation. With the rise of mmWave, RF, and chiplet architectures, the associated test PCBs (load boards) are facing new design challenges. Whether it’s ensuring high-speed signal integrity, efficient heat dissipation, or structural stability in large-format boards, even slight deviations can lead to data distortion or unreproducible failure modes during validation.

Particularly over the past year, the pace of high-frequency adoption has accelerated, while package validation timelines have become increasingly compressed. This has further elevated the role of test board design. In one example, socket contact instability occurred during burn-in testing. The root cause was traced to minor board warpage from repeated high-temperature cycles, resulting in compression misalignment between the package leads and socket contacts—ultimately compromising data consistency.

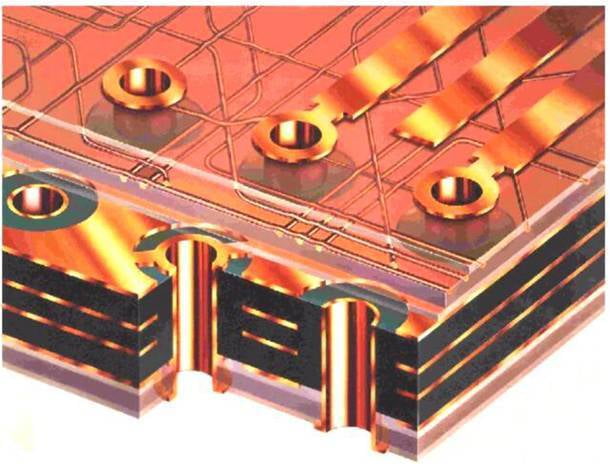

In wafer-level IC testing, the Z-axis coefficient of thermal expansion (CTE) of the board material directly impacts the contact stability between the IC and the probe. On multi-point compression platforms, the board’s ability to maintain flatness under heat stress becomes even more critical. In addition, controlled trace width and consistent impedance are essential for ensuring measurement accuracy at high speeds. These requirements cannot be guaranteed by layout specifications alone—they demand a synthesis of material selection, layer stack-up strategy, and manufacturing precision.

As validation demands grow increasingly complex, the role of the test board is also evolving. It is no longer merely a passive carrier, but a highly customized platform that must align with verification logic while meeting mechanical and thermal reliability requirements. Stability and precision are baseline needs; signal and structural consistency under dynamic conditions is what defines a capable board today.

Against this backdrop, partners with expertise in multilayer board design, knowledge of high-speed behavior, and agile support for sample iteration and manufacturing tuning have become essential collaborators throughout validation workflows.

We’ve observed that in high-frequency, high-temperature validation environments, the stability and structural integrity of test boards are rapidly becoming potential bottlenecks in the test flow. Maintaining signal and mechanical consistency under dynamic operating conditions is no longer just a matter of material choice—it’s a systemic challenge involving both design and production. As we continue to track these evolving application scenarios, we welcome the opportunity to exchange insights if your team is facing similar challenges in test development.

MLB

MWB