Compared with solvent-based vanity water, non-solvent vanity water has the advantages of fast drying, low volatility, environmentally friendly, low-temperature baking, and storage convenience. However, when using non-solvent varnish, it needs to be matched with a curing agent (Catalyst). How to select an appropriate ratio according to the production conditions to improve production efficiency is the key.

Ⅰ. The proportion of Vanish and hardener

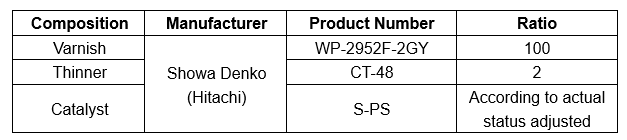

We take Hitachi Chemical's Vanish WP-2952F-2GY for transformers as an example:

Under normal circumstances, the amount of catalyst added is about 1% to 3% of Vanish. The more the catalyst is added, the faster the reaction (curing) speed and the beter the efficiency will be, but at the same time the stress becomes higher and the cost is slightly higher.

We suggest adding about 2% of catalyst is a better choice.

Vanish: Catalyst = 100: 2, in order to effectively increase the reaction rate, the baking time should be shortened, thereby improving production efficiency.

Ⅱ. Mixing management of Vanish

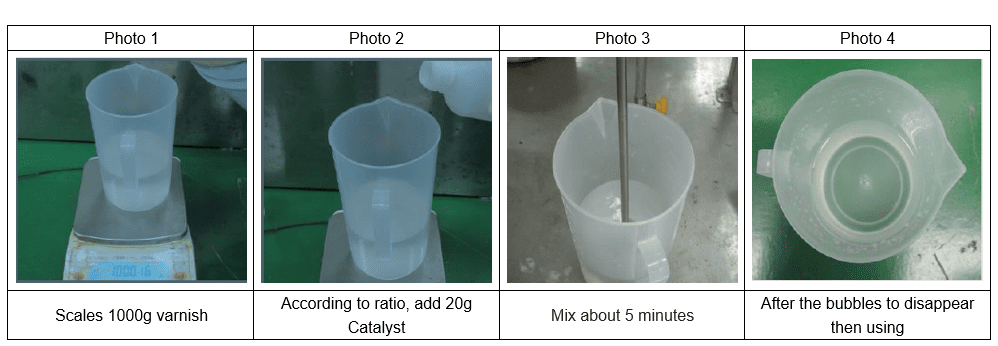

After Vanish and catalyst are mixed, they must be stirred evenly before use to achieve better use efficiency. The proceed is as follows:

1. In a suitable container, add the required varnish, weigh and record. (Photo 1)

2. Weigh the corresponding curing agent at a ratio of 2%, and add it to the vanity water in step 1. (Photo 2)

3. Stir immediately. Pay attention to the vanity water on the wall and bottom of the container which should be stirred evenly.

A. Use a blender to mix about 5 minutes.

B. Manually stir for 10 minutes.

4. Add diluent and stir again for about 5 minutes.

5. Do not stir too fast to avoid air bubbles. Confirm that there is no foaming in Vanish; if there is foaming, please wait for the bubbles to disappear before using(about 30 minutes).

For the convenience of customers, our packaging directly matches the on-site configuration.

Hitachi Vanish WP-2952F-2GY 18Kg/barrel

Catalyst CT-48 0.36Kg/can

When using it, just use one bucket of Vanish with one can of catalyst.

Ⅲ. Vanish management method

1. When storing vanish and catalyst, avoid direct sunlight and keep the temperature below 35℃.

2. Fireworks and heat sources are strictly prohibited.

3. Mixing water and other substances is prohibited.

4. Manage and use according to the first-in first-out method

Related Products

Hitachi Chemical's non-solvent varnish is one of the leading brands in the market. There are many types, meeting various UL temperature requirements (150~220℃); it can be matched with mainstream EIS specifications and suitable for transformers, stators and rotors of electric tools, etc.